Control Plan Software

The control plan contains all vital information regarding the quality assurance measures performed along the production workflow of a product. It was initially developed within the framework of the automotive-specific ISO/TS (IATF) 16949 / QS9000 regulations and specifies aspects such as what inspection methods, tools, frequencies, or tolerances should be used and what containment measures should be applied in case of severe faults.

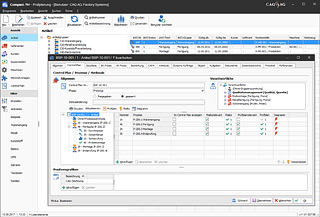

Control Plan

Control Plan

Fully Integrated

Apart from facilitating the creation of IATF 16949 compliant control plans, the Control Plan Manager in CAQ.Net also allows you to identify and define all relevant product/process characteristics that are to be monitored throughout the production process. For this purpose the manager allows you to consistently link the control plan, inspection plan, operating plan, and bidirectionally integrate the FMEA. In this step of the advanced product quality planning process (APQP), possible risks resulting from the product itself or its production process are analyzed and included in the control plan as characteristics that are to be supervised.

The consistent deployment of quality assurance measures throughout the production process brings together information which can be used to create a knowledge base that provides a clear overview of all processes from incoming goods inspection to production, assembly, final check, and shipping. Knowledge management with the Control Plan Manager is rounded off by the possibility to directly adopt characteristics from within the knowledge base, drawing (CAD), or external measurement software (QDAS).

A Dynamic Matter

In order to be able to effectively use the “control plan” instrument, the one-off exchange of knowledge between the individual quality management modules does not suffice, as said exchange must be dynamic and available along the entire production process and beyond. That is why the Control Plan Manager in CAQ.Net consistently monitors all interactions between the control plan, FMEA, inspection plan, and operating plan. It even goes one step further and facilitates the creation of a control circuit between complaints and FMEAs. The initiation of actions in case of changes and corresponding due-date tracking as well as real-time notifications are further aspects that underline the dynamic potential of the CAQ.Net Control Plan Manager and its sophisticated linkage of Quality Inspection Software, Risk Management Software, and Complaint Management System. Said dynamism also includes the simple drag & drop creation of FMEAs, inspection plans, and operating plans from directly within the control plan.

CAQ.Net: The Knowledge Base

By facilitating the continuous adoption of quality assurance data, the CAQ.Net Control Plan Manager allows you to create a knowledge base for your company that transparently displays all experience and information that has been gathered in past projects. This knowledge can then be used for future projects – thus exhibiting the true spirit of Best Practice & Lessons Learned.