CAQ-Software at KIMW: Quality Right from the Start

At the beginning of every quality assurance effort lies the individual measurement value. If this value is measured incorrectly, the collected data is unreliable and has an undesirable effect on all downstream quality management processes. The Kunststoff-Institut Lüdenscheid relies on CAQ AG’s software solutions for gauge and qualification management in order to ensure consistently trained and qualified employees, calibrated test equipment, and valid measurement values right from the very beginning - even in today’s age of working from home and decentralized e-learning.

Plastics Technology Professionals

When dealing with such an incredibly flexible material such as plastic, one rock-solid factor must never be underestimated: quality. The Kunststoff-Institut für die mittelständische Wirtschaft NRW GmbH (KIMW), founded in 1988, is an institute made up of absolute plastics technology professionals and is dedicated to research regarding techniques and measures in the field of quality assurance for the plastics industry. The institute is certified according to DIN EN ISO 9001 and has been operating a testing laboratory accredited in accordance with DIN EN ISO/IEC 17025 since 2000, as well as an international round robin test series accredited according to DIN EN ISO/IEC 17043:2010.

A Quality Mindset

Implementing a company-wide quality mindset is the key to securing the future of any organization. Establishing said mindset can, however, only be achieved if every individual employee can join in on the challenge and continuously improve himself via ongoing training measures. At KIMW, 102 experts are devoted to research in materials, process, tooling, surface, process, and testing technology. Among other items of equipment, 12 injection molding machines (8 with insertion and removal automation), a compounding system for new material development, and 108 systems for material, component, and surface testing are at their disposal. For the planning, administration, control, and implementation of its internal qualification measures and the management of its vast array of inspection equipment, KIMW relies on CAQ AG’s CAQ.Net software solutions.

Enter Dedicated Software Solutions

While Excel spreadsheets were initially sufficient for the small number of employees, handful of gauges, and easily manageable number of training courses, this type of solution soon proved to be outdated for the institute, not least due to its consistent growth in personnel. The risk of incorrect entries, data duplications, or version conflicts had become too great, as had the danger that individual gauges, employees, or training courses could simply be overlooked.

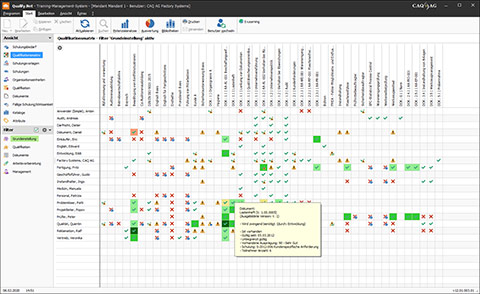

At the beginning of 2016, KIMW therefore began searching for a holistic software solution that would manage the institutes training courses and test equipment in the future. After extensive market research, they found what they were looking for at CAQ AG. The company’s portfolio offers solutions for both areas, which do not function as self-sufficient islands, but are intelligently networked with one another. With the modules for training management and gauge management, KIMW simultaneously ensures that only persons that have received the latest technical training are allowed to operate the gauges. This is supported by functions such as the qualification matrix. With the matrix, it is possible for all employees at KIMW to find out at any time, down to the individual item of test equipment, who needs which qualifications, who has which qualifications, and for whom which qualifications have expired.

Qualification Matrix and Training Management in One

CAQ AG’s Qualify.Net software that is used for this purpose combines qualification matrix, training management, qualification management, and e-learning in one. It offers everything that is needed for planning, managing, controlling, and implementing the various qualification measures at KIMW. The system thereby supports the fulfillment of documentation requirements according to ISO 9001 and enables the creation of an expressive, easy-to-maintain qualification and training database. Last but not least, thanks to comprehensive e-learning functions, the software also makes it possible to tap the full potential of employees and thus set the course for sustainable corporate success - even in today’s age of working from home and decentralized learning.

While the focus of training management is clearly on people, the topic of gauge management is obviously more technical. Yet the need for software to replace the prevailing Excel-spreadsheets arose from a similar motivation. Because, due to the growth at KIMW, in the meantime 774 gauges, 373 test plans, and 49 device managers had to somehow be brought under one hat and all correlations between the entities always kept up to date. Today, KIMW uses CAQ AG’s PMM.Net software solution for its gauge management, gauge monitoring, gauge capability testing, and gauge calibration.

Gauge Management Software

The raison dêtre of gauge and test equipment management is actually strikingly obvious: as the only interface between the object that is to be inspected and the resulting measured value, correctly managed test equipment is crucial for monitoring the quality status of products and thus an indispensable precursor for any sustainable quality assurance system.

The skills matrix allows you to precisely trace which employee

The skills matrix allows you to precisely trace which employee

requires training in which area

It is therefore not surprising that, in addition to the seemingly logical necessity of gauge management, numerous standards and legal guidelines also call for a well-functioning and consistently documented gauge management system. Chapter 7.1.5 of ISO 9001, for example, is devoted entirely to the management of an organization’s monitoring and measuring resources. The specifications in this chapter regarding factors such as calibration, adjustment, calibration status, protection, handling, and documentation are intended to ensure the suitability and functionality of test equipment. Furthermore, from a legal point of view, without test equipment management, manufacturers cannot prove in the event of damage that everything possible had actually been done to prevent failure of their product.

Traceability and History

Using sophisticated gauge management software means that the requirements of pertinent standards, specifications, and legal frameworks regarding gauge traceability and history can be fulfilled, as all data relevant to a company’s test equipment is stored in the software and is available at any time at the push of a button. Said data also includes documents such as operating instructions or maintenance certificates. In order to keep an eye on the test equipment itself, functions such as integrated check-out and storage location monitoring via barcodes, QR, and RFID are available. The software can even be connected directly to existing storage systems and conveyor mechanisms on the factory floor via interface technology such as OpenAPI.

KIMW Can Now Blindly Trust its Measured Values

With the software solutions for training management and gauge management at its disposal, KIMW now commands state-of-the-art digital tools that significantly assist the institute’s everyday processes. Thanks to their modular design and the easy definition of individual KIMW-specific interfaces, the solutions are both similar in appearance and operation, and - regardless of whether it is training or gauge management - KIMW employees always operate in the same simple and intuitive software environment they are familiar with.

The implementation of CAQ AG’s software solutions led to considerable time savings at KIMW, for example, by eliminating the need to search for specific data. At the same time, potential errors due to redundant data or overlooked inspection equipment, trainings, or employees were eliminated. All of the software-supported measures concerning training and inspection equipment management mean that KIMW can today always blindly trust its measured values - for quality, safety, and reliability right from the start.

Additional Links