CAQ-Software at TI Automotive: Braking Quality

If you are traveling on the highway at high speeds and have to use your brake suddenly, chances are you’re not thinking of the company TI Automotive. But, nonetheless, at that moment there exists a close connection between the driver, his or her intention to reduce the speed of the vehicle, and the provider of brake and gasoline lines, TI Automotive.

TI Automotive was founded in 1925 as Mecano GmbH and began manufacturing the so called double wall Bundy tubing. TI Automotive, now an American-English corporation, acts as a supplier to automotive manufacturers worldwide. The company, located in Heidelberg, home to 20,000 employees and active in 29 countries, specializes in multi-layer tubing. Within the “Brake & Fuel” department there exists close collaboration between staff members. The subsidiary locations in Gifhorn, Neunkirchen, and Neuntraubling were chosen for a good reason. Each of the four locations is located in close proximity to one of the major German automobile manufacturers which makes prompt deliveries possible to the respective OEMs, such as Audi, BMW, Daimler Chrysler, or Volkswagen.

In order to adjust the production procedures to address optimally the demands of the respective automobile manufacturer TI Automotive even went one step further: While the tubing producer located in Heidelberg fabricates unprocessed tubing products, albeit of varying diameter and material, the subsidiaries at the other locations produce custom products, varying in length, form, and processed in different ways, ready to be installed into the individual models of the respective automobile manufacturer. Of course, TI Automotive also manufactures ready-to-install bundles (pre-mounted brake and fuel lines).

A Competitive Edge through “Coating Strength”

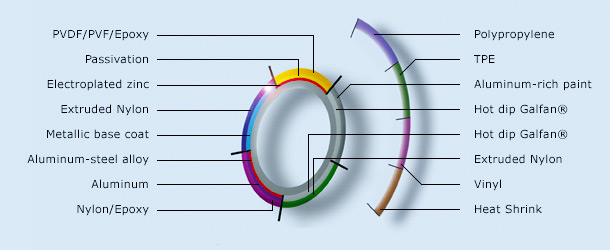

The type of manufacturing employed at TI Automotive makes the lines unique. Highly durable lines are constructed by way of double-rolling steel bands to form tubes, with a diameter between 4.7 and 8 mm. These extremely robust lines, with their double-wall strength, can resist pressures of up to 1,500 bar. TI Automotive products, supplemented by an aluminum alloy coating, guarantee to satisfy the high demands of automobile manufacturers. TI Automotive is especially proud of its coating made of 80 µ aluminum and a sealing polyamide with a resistance strength of 120 µm.

Conductivity through Quality

Of course, it is self-evident that highest quality demands must arise in the production of components like brake and fuel lines since these are vital parts when it comes to safety. That’s why all four of the TI Automotive locations with “Brake and Fuel” departments possess an independent quality team, consisting of qualified employees, a supervisor for quality management, and an engineer in charge of quality matters.

Of course TI Automotive also possesses safety certifications according to the latest criteria for Quality Manager Germany. Employing norms such as DIN EN ISO 9000 or ISO/TS 16949 is just as much a matter of course for quality manager Thomas Müller-Adams as is using a high performance software system to ensure quality assurance.

For TI Automotive the software of choice in matters of quality assurance is, of course, CAQ AG Factory Systems. After all, TI Automotive has been using CAQ AG software since 1994 without even once giving a fleeting thought to a switch to another software system or software provider.

“We use the CAQ AG software at each of our four locations in our German production line”, Mr. Müller-Adams explains. The cooperation between the software provider and the automobile parts manufacturer has blossomed from a personal relationship to broad collaboration. This development is largely due to the software’s impressive cost-operation ratio and the possibilities for adaptability inherent in the software’s design.

Top Service in a Package

The companies’ business relationship began in 1994 with the first SPC-module and has expanded, over the years, to a broad application of CAQ AG software in the areas of inspection planning, inspection data acquisition, evaluation, and analysis. And, in order to continue this fruitful relationship in the future, TI Automotive makes ample use of CAQ AG’ workshops and training sessions: “With 20 licenses we receive, as part of the TSP (Top Service Pack) offer, access to a number of free training opportunities. Of course it is important for our employees to continually be up-to-date on the latest developments in the software and therefore be able to put the system to use optimally.”

In spite of using the CAQ software in different locations spread all over Germany, the 20 licenses sufficiently cover the automotive parts manufacturer’s usage. The advantage of multiple installations, in comparison to other software providers, is the significant savings over conventional license agreements. “CAQ AG software does not make licenses dependent on the number of installations, but rather on simultaneous users at any given time. Since we never have more than 20 employees accessing the system at one time, this allows for significant savings”, according to quality supervisor Thomas Müller-Adams.

Price and performance of CAQ software has convinced the quality expert. Mr. Müller-Adams also appreciates the fact that he can count on support not only in areas of financial considerations but also when it comes to technical difficulties. A technical advisor will even provide assistance at the manufacturer’s location if need be. These criteria have convinced Mr. Müller-Adams to continually depend on CAQ AG software in the future.

Additional Links