CAQ-Software at Aicher: Top Gear – A Quality Transmission

Vehicle transmissions are highly complex devices and it comes as no surprise that the parts utilized within are subject to extreme physical forces. Revolutions are counted in steps of thousands and the operating temperatures range across a scale of almost 200 degrees Celsius – from outside temperatures of way beyond zero degrees in arctic climates to well into the hundreds when the transmission is in use…and the levels of torque that are transmitted are quite sufficient enough to uproot entire trees.

Bolts for Transmissions and Engines

Bolts for Transmissions and Engines

In this hostile environment, highly precise components from cogwheels to screws and shafts must now work together faultlessly – with absolutely no tolerance and margin for error. Two factors are an absolute necessity in order to be able to ensure this: precision and quality. The cogwheels, for instance, must grip into one another perfectly, regardless of how demanding and stressing the situation inside the transmission may be, as even the smallest deviations or flaws in the material would inevitably cause damage to the entire unit.

Precision Parts for Powertrains

Aicher Präzisionstechnik GmbH & Co. KG from the town of Königsheim in the southwest of the Swabian Alps produces parts for transmissions, motors and pumps, and must guarantee the quality and precision of millions and millions of these parts. The family-owned company can look back at a proud and successful tradition spanning well over fifty years, during which it has produced countless mechanical parts that fulfil their duty deep inside the hearts of millions of cars all over the world. From turned or milled parts to entire selector shafts and other assemblies: the 130 man strong company produces key components for the automobile industry without which mobility on the roads would come to a very sudden standstill.

Aicher Präzisionstechnik produces drive parts that are used in motorbikes, cars, construction vehicles, trains, ships, yachts, farm machinery or industrial printing equipment. Regardless of whether for VW, BMW, Audi, Mercedes, Porsche, Bugatti, Bentley or Ferrari, MTU, ZF, Getrag or Heidelberger Druckmaschinen: Aicher directly and indirectly supplies some of the internationally most renowned companies with a variety of precision parts.

In order to be able to consistently safeguard and ensure the quality of these parts, it is indispensable that a comprehensive quality management system be put in place. Such a system must not only support standard-compliant working and exhibit a high degree of user-friendliness, but also be future-proof and consistently scalable in order to tackle the production challenges of tomorrow. Following a painstaking research and evaluation procedure with regard to these factors more than ten years ago, Aicher Präzision chose CAQ.Net – the management system of CAQ AG Factory Systems.

A Comprehensive Quality Management System

Aicher Präzisionstechnik Company Headquarters

Aicher Präzisionstechnik Company Headquarters

The modular structure of the CAQ AG portfolio allowed Aicher Präzisionstechnik to put together a comprehensive solution that monitors their production quality from beginning to end – all the way from initial product design to subsequent aspects of complaint management.

CAQ.Net‘s consistent database and data structure hereby allows Aicher to apply and intelligently cross-reference information from within all fields of quality assurance and management. Regardless of whether information derives from initial sample tests, incoming goods inspections, FMEAs, preventative maintenance tasks, or audit management processes: the parallel and cross-modular fashion in which CAQ.Net manages data provides the quintessential framework for sophisticated quality management. QDrive.Net – the central quality overview module of CAQ.Net – provides a single interface from which users can access every individual module and thereby monitor and control the overall quality situation in the company. It, for instance, enables precise filtering for specific articles, customers, suppliers, machines, persons, or processes and thus provides a real-time overview of all quality-related data or occurrences in the company.

Multi-Point Measurements

The quality planning, inspection, and evaluation module Compact.Net forms the heart of Aicher’s quality management system. Amongst other areas of application, they use it for final inspections within the framework of highly sophisticated multi-point measurements. A multi-point measuring device comprising up to 14 parallel gauges is hereby used to examine the precise fitting of complex assemblies which each consist of between 2 and 41 individual parts. The assemblies are placed into the measuring device and – at the push of a button – 17 values are simultaneously acquired and fed directly into the CAQ system. The data is then available for further companywide processing immediately. Aicher Präzisionstechnik also uses fully automated Zeiss measuring devices. These are automatically supplied with parts via a robotic arm and transmit the gathered measurement data to the CAQ system via APE.Net, the module for automatic inspection data acquisition of protocol-ready testing and measuring machines.

Always Perfectly Calibrated

Faultless, calibrated, and accurate gauges are an absolute necessity for Aicher Präzisionstechnik, as the true reliability of measurement information is determined right when it is initially acquired. In order to ensure that all gauges are always calibrated correctly, the company uses PMM.Net – CAQ AG’s gauge management module. PMM.Net allows Aicher to continuously monitor the condition, calibration status, storage location etc. of the over 6000 gauges that are used in their production facility. PMM.Net also serves as a perfect example by which to describe the fully integrated and transparent CAQ system, as only those gauges may be employed for measuring processes, that are available and in good working order.

Complaint Management

The CAQ.Net modules also interact perfectly when dealing with complaints. Aicher Präzisionstechnik uses the complaint, rejection, and service management module REM.Net for the processing of both internal and external complaints. Here the various modules also work together in close cooperation and provide a structured overview of the interconnection between all quality-related data in the CAQ system. This allows Aicher to create complaints directly during the inspection data acquisition procedure in Compact.Net and thus immediately react to even the minutest anomalies in the production process. By implementing REM.Net and the other CAQ.Net modules, Aicher was able to significantly improve the overall quality parameters and reduce off-quality production.

Certified

In order to be successful in the automotive sector, the attainment of required certificates and the precise application of standard-compliant production methods are absolute necessities.

Aicher Präzisionstechnik has, for instance, implemented and consistently adheres to the quality management standards ISO 9001:2008 and ISO/TS 16949:2009 as well as the environmental standard DIN EN ISO 14001:2004, AC:2009 and the voluntary environmental management instrument EMAS (Eco-Management and Audit Scheme ). Adherence to these rules and regulations is verified in regular audits. In order to ensure that everyone is always perfectly prepared for these audits, the company uses the audit and checklist management module QAM.Net. Freely definable questionnaires in QAM.Net allow Aicher to model every process, product specification, and system detail of the company or area of responsibility. These models can extend to up to six question levels in depth and contain freely definable evaluation schemes – from simple yes/no decisions to highly complex qualitative question appraisals. The companywide document management processes are controlled via QBD.Net – CAQ AG’s module for quality-related document management. It is used for the maintenance and management of company-internal documents as well as customer and DIN standards.

Trained

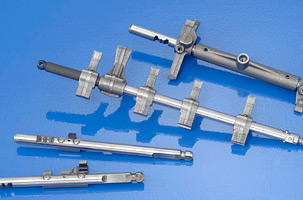

Selector Shafts

Selector Shafts

Aicher Präzisionstechnik is well aware of its corporate social responsibility (CSR) and therefore takes the company-internal training and development of its employee very seriously. It recruits its employees locally and instructs them in long-term training initiatives – 8 apprentices are currently undergoing training. Just like a perfectly interlocking cogwheel, the training-management-system Qualify.Net is now being introduced at Aicher where it is elegantly interweaved with the existing CAQ system. It fits right into the CAQ.Net quality transmission and links itself to the existing database and data structure. This means that the company can today plan and organize the employee training and quality assurance of tomorrow.

The Gold Standard

In the year 2010 Aicher Präzisionstechnik produced and assembled the 1,000,000th selector shaft for the Getrag transmission that is used in the 1, 3, and 5 Series BMW. The shaft was, however, not used in a vehicle, but was instead gold-plated and given a special presentation spot at Getrag’s HQ. Aicher is now rapidly approaching the next million selector shaft – with over 1200 shafts produced per day, this record too will most certainly be broken very shortly. When dealing with production volumes like this, the comprehensive assurance of precision and quality can only be achieved by employing an intelligently designed, perfectly balanced, and consistently expandable quality management system like CAQ.Net.

The Quality Transmission

The parallels between a vehicle transmission and a modular quality management solution may not become apparent at first glance. However, both are systems in which the precise interplay of the parts determines the performance and overall usability of the system. The individual modules of a software solution must interweave perfectly with on another – just like the cogwheels of a transmission. Whereas transmissions channel kinetic energy across complex parts and assemblies, CAQ solutions do exactly the same with quality-related information. Both systems have one key aspect in common: absolutely no margin for error.

Additional Links