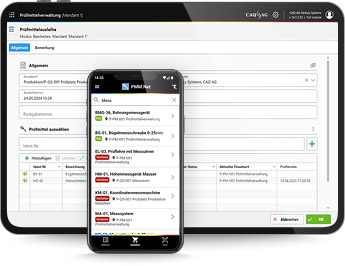

Calibration Management Software PMM.Net

Calibration Management Software PMM.Net

Digital Calibration Management

From simple calipers to the most complex multi-dimensional gauges: As the reliability of information is determined right at the point of its initial collection, perfectly functioning gauges are essential for successful quality assurance – and the calibration management software PMM.Net ensures precisely that.

The software supports you throughout the planning, administration, control, calibration, and capability analysis of your gauges and thus effortlessly facilitates highly effective and efficient gauge management – including the determination of measuring equipment capability and measuring system capability.