CMMS Software PMS.Net

CMMS Software PMS.Net

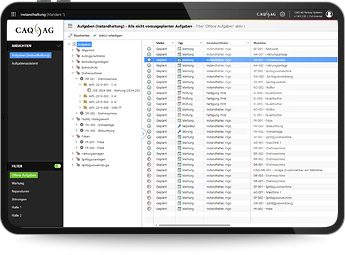

Computerized Maintenance Management System

By utilizing intelligent and usage-related data regarding measured wear and tear, the CMMS software PMS.Net only implements inspections that are truly necessary. It is able to learn and incorporate inspection histories automatically and apply the resulting statistics to future inspection and maintenance activities.

Who needs to do what job when? Why did he do the job and what spare parts did he require? How long did it take him to do the job? How long were we not able to use the production facility? When and how long will the shutdown period last and how long will we be unable to use a specific tool? What personnel resources will be required for the task? The CMMS Software PMS.Net provides you with one holistic and highly intelligent solution for all these tasks. It is a state-of-the-art maintenance, servicing, and repair management system that includes a whole host of monitoring, documentation, planning, and reminder functions in order to ensure that jobs always get done when they need to get done.