CAQ-Software at Seeger-Orbis: Automotive Excellence

Seeger-Orbis GmbH & Co, located in Königstein near Frankfurt, has been producing safety rings and circlips for the automotive industry since 1917. In a total production area of 36,000 m2, 230 employees ensure maximum customer satisfaction by producing high-quality products for this subsidiary of Barnes Group, now operating worldwide.

The company’s list of customers is long. Well-known automobile manufacturers, such as Volkswagen, GM, Ford, Daimler, as well as renowned automotive parts giants, such as ZF, Getrag, or Bosch, only represent a small excerpt of Seeger’s very long customer list. Delivering products to approximately 50 large companies and another 40 dealers, e.g. THF, calls for a nearly unlimited variety of circlip assortments. In addition to over 2,000 standard sizes with universal conformity, Seeger-Orbis’s production range includes over 2,000 special sizes, which are produced for customers according to individual demands and made from spring steel CK75 or patented tempered steel (MK58D) punched out or bent. A subsequent hardening process of the rings in giant hardening ovens as well as attaching different surfaces to decrease corrosion results in high strength and longevity of the final products.

When it comes to the fit of the Hessian company’s products everything must be precise and the shape must adhere exactly to the original template. In addition to producing round, oval, or specialized shapes, the company also manufactures a variety of diameters and thicknesses. The rings have varying diameters ranging up to 2m, used in industrial machine production. But no matter what the size, large and small, all rings have to have similar characteristics.

Quality with System

Quality plays a significant role in Seeger’s daily production and when it is completing large transactions. Seeger-Orbis holds current certifications such as ISO/TS 16949; QS 9000/VDA 6.1, DIN EN ISO 9001 and DIN EN 14001 and possesses an active environmental protection system with its own waste water treatment plant.

In order to retain the highest quality standards in production and product quality, Seeger-Orbis uses CAQ AG Factory Systems’ integrated quality management system. Seeger-Orbis decided to begin using the software system in 1996 based on its excellent performance price ratio. The company was also impressed with CAQ AG’s comprehensive spectrum of options as well as free choice of expansion modules to individually adjust the system to any company’s needs. The modules represented an outstanding value and allowed CAQ AG software to emerge as the clear winner in a group of 3 of its competitors.

Modular Variety

The quality control software, employed in the various areas of production, was adjusted to fit Seeger-Orbis’s needs perfectly. In addition to nine licenses of the base module Compact.Net Seeger also purchased the programs for gauge and rejection management as well as initial sample inspection. They company also employs other modules, e.g. the form generator and others, as a matter of course.

Michael Stamm, certified engineer at Seeger-Orbis, is responsible for CAQ AG software. As the responsible representative for investments in areas of production and processing technology, he was charged with acquiring a software system for quality control in 1995. For Michael Stamm it was not only the initial purchase investment that played an important role in the software choice but also the system’s performance and options. Today, Seeger-Orbis has installed a terminal for SPC data acquisition at every processing point from product entrance to product exit and final inspection. Here, the appropriate data is classified according to batch and production processes and documented in a subsequent report. In this manner all customers, if so desired, may get a comprehensive quality confirmation of his or her requested product at any time.

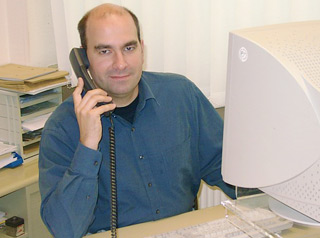

Dipl.-Ing. Michael Stamm

Dipl.-Ing. Michael Stamm

Production and Processing Supervisor

Executives in Seeger-Orbis’s company management also see the purchase of CAQ AG software as a smart investment. Mr. Abeling, CEO and production supervisor, is always interested in innovations and expansions of his software system, which will enhance quality control and therefore save the company money. Michael Stamm is also interested in new CAQ AG products: “There is always room for improving quality …”

Mr. Stamm, as production and processing supervisor at Seeger-Orbis, is responsible for ensuring that the company’s investments are sound. He has long surpassed the point where his initial investment has turned to profit. That’s why Seeger-Orbis is planning on purchasing expansion modules for its software system. Mr. Stamm also takes advantage of training sessions at regular intervals offered by CAQ AG.

“In these free user workshops our employees can learn tips and tricks to use the software more efficiently! And the up-close and personal contact with CAQ AG’s employees has transformed our relationship from purely business to one of friends.”

Additional Links