Töpfer and CAQ AG: Quality and Safety for the Next Generation

It’s amazing, but a baby’s brain at birth already has as many neurons as an adult brain, yet it weighs barely a quarter of the adult brain. This is because the infant neurons are not yet fully grown and the number of neural connections increases enormously during development. In the course of the first year of life, the weight of the brain triples. This requires an enormous amount of energy and thus food intake on the part of the infant. In a metaphorical sense, similar applies for computer software systems.

With its about 195 employees, the company Töpfer GmbH produces exclusively certified organic baby milk formula and baby porridge, as well as BDIH-certified natural cosmetics for babies and moms. Max Töpfer laid the foundations for the company in Böhlen near Leipzig in the year 1911, and today the Allgäu-based family business is one of the leading producers of organic baby food & natural cosmetics, available in over 25 countries worldwide.

CAQ AG’s CAQ.Net software solution has been watching over the quality and safety of Töpfer GmbH’s products and individual production processes for over 25 years now. This today full-blown software solution, however, also once upon a time started off as a digital new-born.

Born to Become an Achiever

A software system is actually quite similar to a small child. Especially in the introductory phase, it is important that the system is fed with the right data, that the right structures are set up, and that the course is set early on in the direction of a system that will be truly lived by future users. This applies especially for quality-related systems, because, after all, quality itself is not an automatism. No simple button-pushing and the desired product quality mysteriously appears. To be honest, true quality requires hard work and always a good pinch of passion. Just meeting standards is something almost anyone can do. But providing the market with the safest and highest-quality products requires much more.

Raised with Quality Excellence in Mind

In order for a CAQ software system to be able to make full use of its excellent genetic assets and later achieve great things, it must be consistently supported, especially in the initial implementation phase. The foster father of the system at Töpfer is Raimund Hils, head of quality management at Töpfer GmbH. The CAQ.Net system saw the digital light of day at Töpfer back in the year 1995 and Mr. Hils, together with CAQ AG’s technical support, quickly got the system up and running. Where should the system head from a business strategy standpoint? Which modules should be implemented, which employees should be allowed to "play" with the system, and how can it be ensured that it is fed only with nutritious information and not just with dull data? All of these questions were asked and, thanks to Mr. Hils’ many years of experience in the food industry and CAQ AG’s vast expertise in software and IT infrastructure, answered in such a way that CAQ.Net’s course was set in the direction of a full-fledged quality control center right from the word go. It was clear to everyone involved in raising the system that it would one day achieve great things.

Learning to Walk

Digital step by digital step, the CAQ software system at Töpfer GmbH learned to walk and has long since come of age. The system can now easily handle a full-blown audit or a detailed evaluation - it stands firmly on its own two feet. But let’s take a look at what the software is used for at Töpfer today and how it supports the employees there.

Modular Down to the Minutest Detail

Töpfer uses a wide variety of CAQ software modules. The Process.Net module for process management, for example, is used to create and manage process workflows, process descriptions, and HACCP flow charts. The Risk.Net module is used to create risk and HACCP analyses as well as to monitor food defence and food fraud. The QAM.Net module for audit management is used to plan, document, and evaluate audits such as internal audits, plant inspections, supplier audits, or glass registers.

The Compact.Net module for inspection planning / quality inspection is used to create inspection plans, record inspection orders, and generate evaluations. The REM.Net module for deviation/nonconformity management is used to process complaints and evaluate them. Finally, the PMS.Net maintenance module is used to plan, document, and evaluate all maintenance tasks and the PMM.Net gauge management module is used for gauge monitoring.

A Focus on HACCP and Documents

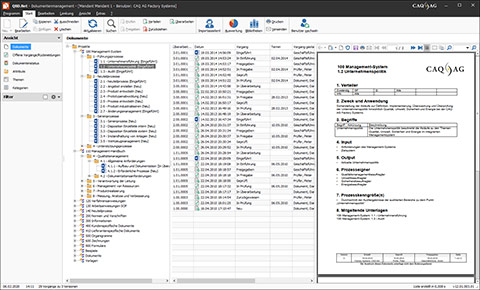

The topics of documents and HACCP play a particularly important role at Töpfer and are handled with the QBD.Net module for document management. In addition to providing access to specification documents and other information, QBD.Net is used to collect and evaluate all important food safety information at Töpfer. This includes risk analyses (e.g. HACCP), revision checklists, process descriptions, product group descriptions, CCP/oPRP plans as well as assessments of individual CCPs/risks and verification plans.

Verification records relating to evaluations of employee training, maintenance, test equipment, inspections, audits, or deviations are also securely managed in the QBD.Net module. Training documents for e-learning and classroom training round out the portfolio of documents managed with CAQ.Net software.

Quality in Times of Crisis

The CAQ.Net software solution at Töpfer proved itself especially in times of crisis. During the Covid 19 pandemic, digital and fully networked software systems such as CAQ.Net were able to clearly demonstrate their unique digital advantages at a very early stage and react quickly to new circumstances in a way that would have been simply impossible with traditional means such as pen and paper. Central to this reaction was the topic of training management. Originally only responsible for planning and documenting training courses, the Qualify.Net module for training management with its diverse e-learning functions in conjunction with the WebCAQ.Net web applications allowed training operations to be seamlessly maintained even when employees were working from home. Among other things, the Risk.Net module, which enabled new safety and risk assessments with regard to the situation, and the QAM.Net module, which now specializes in hygiene inspections in an expanded form, were also able to adapt quickly to the new circumstances.

As the year 2020 showed, new business challenges always bring new tasks for the CAQ software system at Töpfer. But it was already clear to everyone involved in 1995: This system will one day achieve great things. And as predicted, it has developed splendidly and has been in use for over 25 years now. The little CAQ system from years ago has really come of age.

Additional Links