ISIR Software for PPAP / Initial Sample Inspections

Initial sample inspection, inspection planning, and ISIR initial sample inspection report in one software including PPAP, FAI, VDA, and QDX. The ISIR software EMP.Net includes everything you require for planning, executing, maintaining, and printing initial sample inspection reports. From sample management and data entry to evaluation and documentation – conduct all sample-related jobs with just one software. Use the sophisticated auto-functions, CAD-integration, pre-defined reports, and evaluations of the software in order to reduce the work involved in the initial sample inspection process to a minimum.

Advantages of the ISIR Software

- Standard-compliant planning, administration, and execution of sample inspections

- Measurement / function / material / reliability / visual / attributive / assembly inspections

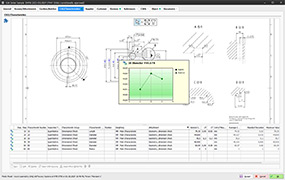

- Import inspection characteristics and specifications from CAD-drawings (e.g. DXF, DWG, IGES)

- Integrated CAD-Viewer

- Fully integrated in the quality inspection software Compact.Net

- Initial sample tests compliant with ISO 9001, QS 9000 (PPAP), VDA (PPF), and IATF 16949

- Automated stamping of drawing characteristics

- Connect measuring devices, inspection robots, and laboratory equipment

- Multi-language support for dynamic and master data

- Comprehensive selection and sorting criteria

- Supports a variety of interfaces and multi-dimensional gauges for online measurements

- Direct access to applicable, implemented, and controlled QBD.Net documents

Functions of the ISIR Software

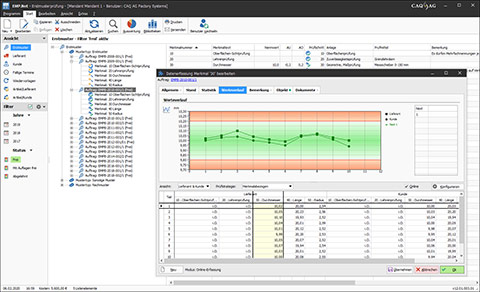

Due to the complexity of the tasks involved and the variety of different information sources that need to be combined, there are considerable risks involved in the manual creation of paper-based initial sampling reports – the time expenditure required for the manual creation of an ISIR is, of course, also immense. The usage of the software solution provides a great number of advantages that facilitate a considerable improvement in both efficiency and precision. In the software, you work directly in a dedicated initial sample tree structure in which you simply select the respective supplier or customer and assign the relevant inspection plans and characteristic structures to them at the push of a button.

Used e.g. as PPAP Software, EMP.Net then systematically guides you through the creation of a standard-compliant initial sample report in accordance with automotive requirements and provides you with all systemwide information right at the point where you require it.

The direct exchange of systemwide information is one of the main drawcards of EMP.Net, as data from a variety of areas such as gauge management, risk analysis, or control plan can be brought together in a single document. It is, for instance, possible to exchange characteristics between the control plan and the ISIR Software and vice versa. The software also allows you to easily include and stamp CAD-drawings in a variety of import formats such as DXF, DWG, or IGES. The graphic CAD inspection planning tool CAD-Link.Net can be fully integrated into the software and allows you to retrieve inspection characteristics including specifications (sizes, shapes, tolerances, symbols, and comments) and many additional parameters from directly within your CAD-drawings.

Each CAQ.Net Module Puts the Following at Your Disposal

- Management of systemwide actions and tasks

- Definition of attributes for all relevant entities

- Configuration of role concepts and access rights

- Use of multilingual application & transaction data, incl. translation tool

- Application in multi-tenant mode for cross-location and cross-database scenarios

- Modification of module-specific content and interfaces

- Creation and modification of reports and e-mail templates

- Analysis and evaluation of systemwide data across all CAQ.Net applications

- Data validation via Audit Trail

- Automated data exchange with existing IT-systems and infrastructures

Standards-Compliance of the ISIR Software

- DIN EN ISO 9001

- IATF 16949

- AIAG (PPAP)

- VDA Volume 2 (PPF / PPA, EMPB / ISIR)

- VDA Volume 6.1

- DIN EN ISO 13485

- DIN EN 9100

- DIN EN 9102 (FAI)

- DIN EN ISO/IEC 17025

- GMP

- FDA 21 CFR Part 820

- IFS

- More Regulations »

ISIR Software FAQ